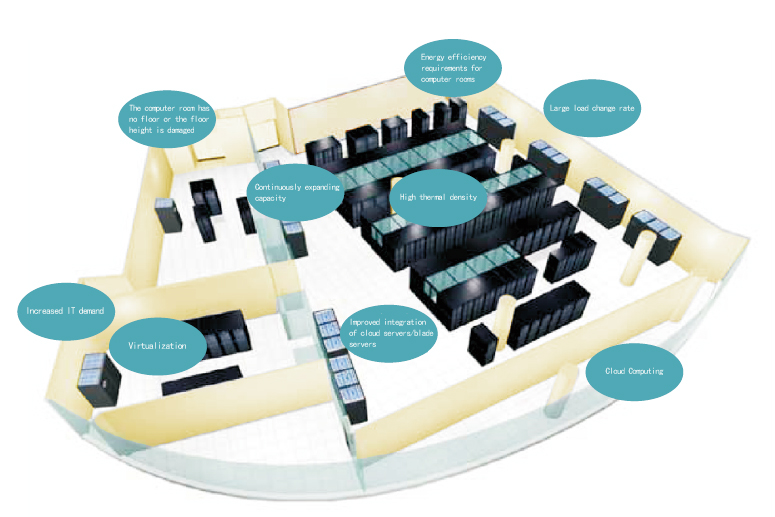

Modular data center efficient cooling system solution

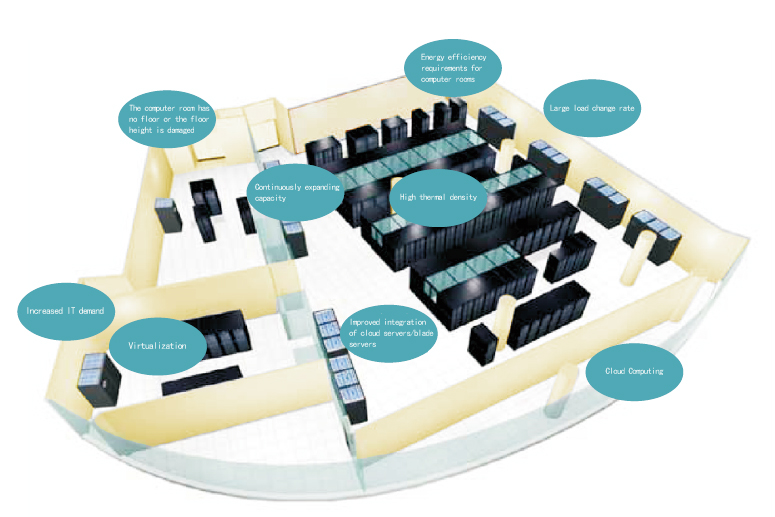

● High thermal density areas in data centers

● Container data center

● Improve EER of refrigeration system

● Fcooling configuration combined with natural cooling source

● Modular data centers

● Reduce the overall PUE of the computer room

● Matching cold and hot channel design

i-Row series cooling

i-Row is an adaptive precision cooling system close to the heat source, ideal for rack level cooling in data centers

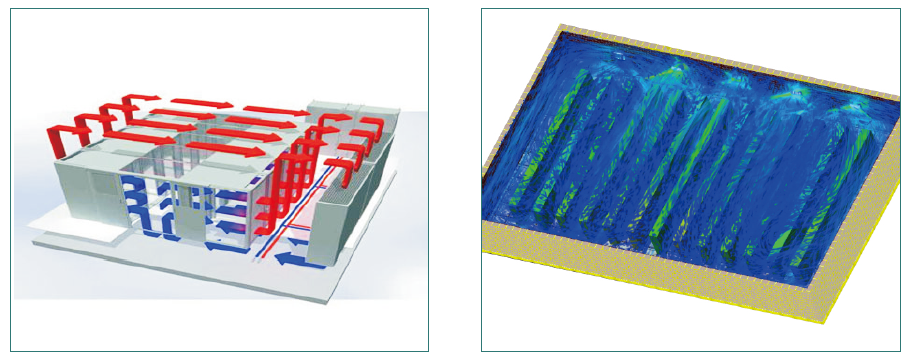

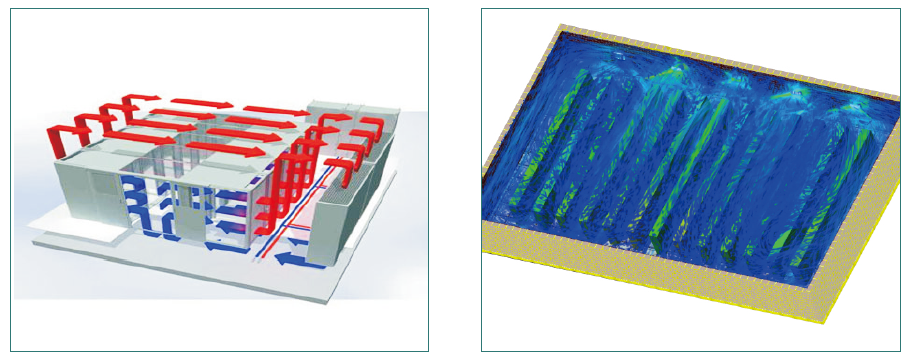

Cold and hot channel applications

Modular, container data center applications

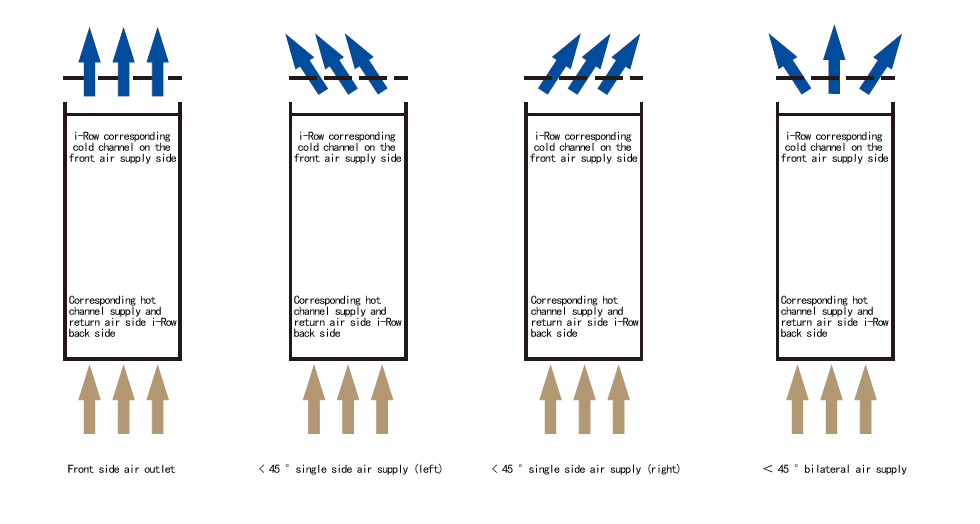

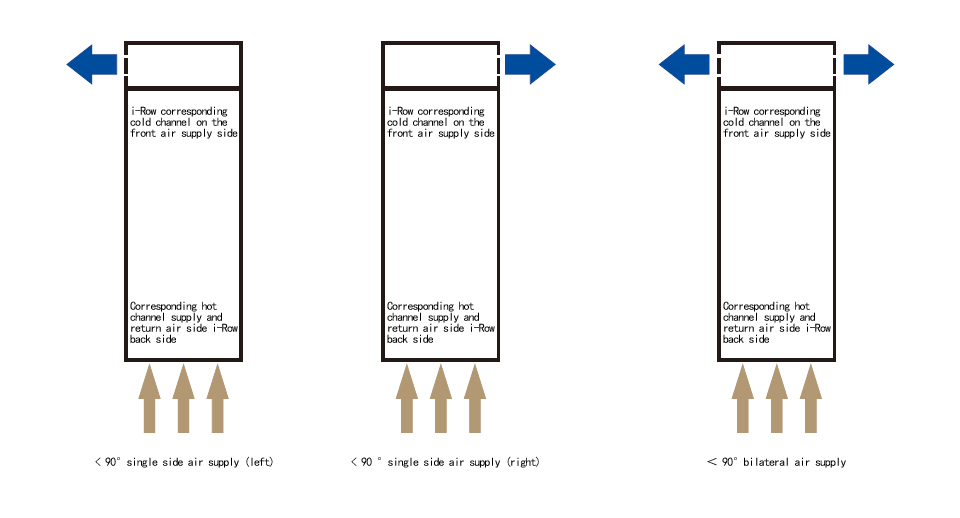

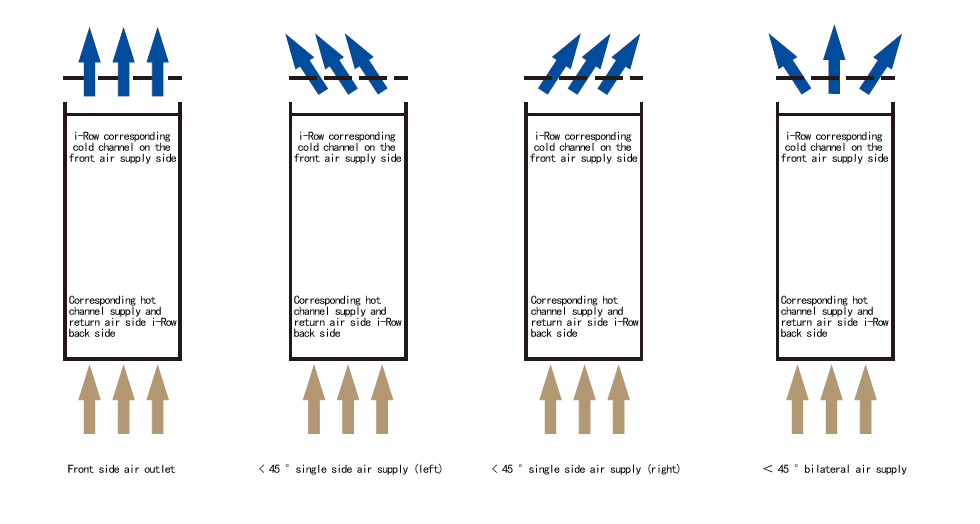

Air supply method

Configuration 1

The unit size is 300/600 (width) x 1200 (depth) x 2000 (height)

Configuration 2

The unit size is 300/600 (width) x 1200 (depth) x 2000 (height)

Characteristics of i-Row

EVO control system

● Visualization display function, including operating status and temperature and humidity of the incoming and outgoing air of the tested cabinet

●Advanced group control function, with over 30 units and the ability to connect no less than 6000 temperature sensors externally

●Standard configuration of SNMP and TCP/IP interfaces

●DC variable frequency EC compressor

●DC variable frequency EC compressor using R410A environmentally friendly refrigeration

●Dynamic cooling to adapt to rapidly changing machine room loads

●Save energy and improve energy efficiency at low loads

●Can greatly reduce the number of compressor starts and stops, improve system reliability

EC fan

●Adopting electronic commutation synchronous EC motor, saving energy by 20-30%

●Soft start function, low starting current

●Automatically adjust the fan speed according to refrigeration demand or air pressure, and provide air volume as needed

●Redundant configuration of fan N+1 ensures full airflow operation even if any fan malfunctions

● Easy to maintain design

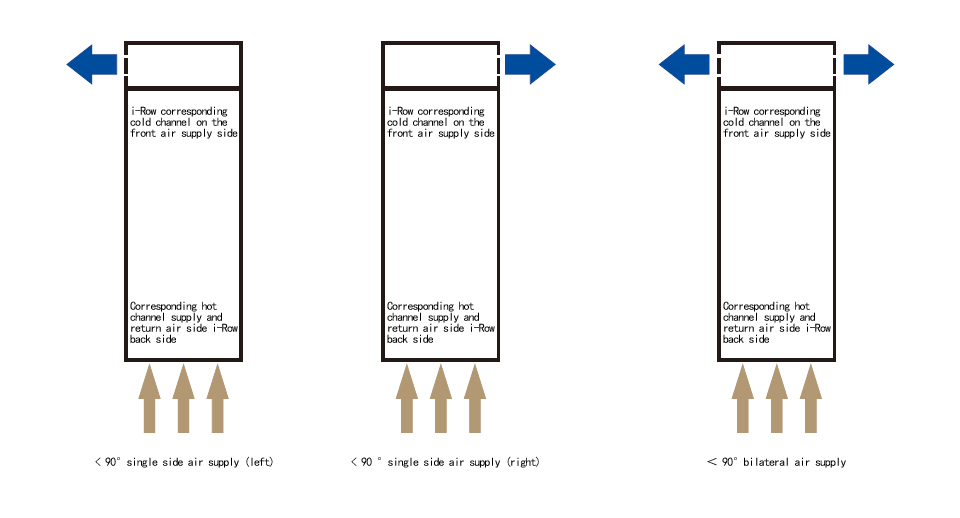

Electronic expansion valve

●Smooth adjustment of throttle opening, combined with variable capacity compressors to achieve energy-saving

●Wide adjustment range, reducing overheating, and improving energy efficiency ratio

●Achieve precise matching of cooling capacity and load

●Fast response speed, achieving precise cooling

Optional accessories

● Dual power input switching switch

● Wireless temperature and humidity sensors

● Air supply deflector device

● Wired temperature and humidity sensors

● Low temperature starting device

● Chilled water three-way water valve

● GPRS SMS alarm

How i-Row Achieves High Energy Efficiency

●Close to the heat source, the return air temperature and evaporation pressure are improved, and the refrigeration efficiency is improved

●The system design of the unit adopts computer-aided fluid dynamics (CFD) calculations to ensure the optimal distribution of airflow within the unit and between racks

●DC variable frequency EC compressor can adapt to rapid changes in server temperature, reduce frequent opening and closing of the compressor, and also improve system reliability

●Advanced EVO controller, controlling air volume and cooling output as needed, combined with EC fan and DC variable frequency EC compressor to achieve the best effect and minimum

●Energy consumption; Multiple control algorithms can be used to calculate the highest and average temperatures, which can ensure effective cooling and effectively reduce the total temperature

●Physical energy consumption

i-Row air-cooled condenser

●Stepless speed regulation owl type fan control

●Extremely low maintenance requirements, suitable for various climatic conditions

inter train cooling

i-Row the model description of the series variable frequency precision inter train cooling between is shown in the table below

Indoor unit model:

sequence number | 1 |

| 2 | 3 | 4 | 5 |

code | IRW | - | LA | 025 | F | RH |

The unit model description is as follows:

Sequence number | code Interpretation | optional |

1 | brand or series name |

|

2 | frequency conversion inter column |

|

3 | cooling capacity | 12.5kW、25kW、40kW、50kW、60kW |

4 | air supply mode | F:send before and then return |

5 | auxiliary heating humidification function | NH:humidification RH:constant temperature and humidity,with auxiliary heat humidification RN:auxiliary heat Noon:single cooling, no auxiliary heating and no humidification |

Outdoor unit model:

Sequence number | 1 |

| 2 | 3 | 4 | 5 | 6 |

Code | IRW | - | CY | 0 | X | X | X |

Note: i-Row-LA series frequency conversion column cooling is composed of indoor unit, controller and outdoor unit.

Parameters of air-cooled indoor unit between columns Model IRW-LA | 12 | 25 | 40 | 50 | 60 |

Function | single cooling | single cooling+ | constant temperature | single cooling | single cooling+ | constant temperature | single cooling | single cooling+ | constant temperature | single cooling | single cooling+ | constant temperature | single cooling | single cooling+ | constant temperature |

electric heating | constant humidity | electric heating | constant humidity | electric heating | constant humidity | electric heating | constant humidity | electric heating | constant humidity |

Air supply mode | F/S | F/S | F | F | F |

Input power supply form | 380Vac/3ph/50Hz | 380Vac/3Ph/50Hz | 380Vac/3ph/50Hz | 380Vac/3Ph/50Hz | 380Vac/3Ph/50Hz |

Cooling capacity (kw) | 12.5 | 12.5 | 12.5 | 25 | 25 | 25 | 40 | 40 | 40 | 50 | 50 | 50 | 60 | 60 | 60 |

Apparent cooling capacity (kw) | 12.5 | 12.5 | 12.5 | 25 | 25 | 25 | 40 | 40 | 40 | 50 | 50 | 50 | 60 | 60 | 60 |

Heating capacity (kw) | 一 | 2 | 2 | — | 3 | 3 | 一 | 6 | 6 | 一 | 6 | 6 | 一 | 6 | 6 |

Amount of humidification (kg) | 一 | 一 | 1 | 一 | 一 | 1.5 | 一 | 一 | 3 | 一 | 一 | 3 | 一 | 一 | 3 |

Form of compressor | variable frequency compressor | variable frequency compressor | variable frequency compressor | variable frequency compressor | variable frequency compressor |

Form of refrigerant | R410A | R410A | R410A | R410A | R410A |

Fan form | Dc EC centrifugal fan | Dc EC centrifugal fan | Dc EC centrifugal fan | Dc EC centrifugal fan | Dc EC centrifugal fan |

Air volume m3/h | 3200 | 3200 | 3200 | 5000 | 5000 | 5000 | 8800 | 8800 | 8800 | 11000 | 11000 | 11000 | 12500 | 12500 | 12500 |

External residual pressure Pa | The standard residual pressure is 20Pa, 0-400 Pa adjustable |

Electric heating form | PTC electric heater | PTC electric heater | PTC electric heater | PTC electric heater | PTC electric heater |

Electric heating kw | - | 2 | 2 | - | 3 | 3 | - | 6 | 6 | - | 6 | 6 | - | 6 | 6 |

Form of humidification | wet film humidifier | wet film humidifier | wet film humidifier | wet film humidifier | wet film humidifier |

Maximum amount of humidification kg/h | - | - | 1.5 | - | - | 1.5 | - | - | 3 | - | - | 3 | - | - | 3 |

Form of throttling | electronic expansion valve | electronic expansion valve | electronic expansion valve | electronic expansion valve | electronic expansion valve |

Air filter | G4 plate filter | G4 plate filter | G4 plate filter | G4 plate filter | G4 plate filter |

Humidifier inlet pipe | G1/2 | G1/2 | G1/2 | G1/2 | G1/2 |

In the condensate drain (mm) | 19 | 19 | 19 | 19 | 19 |

In the refrigerant pipe (mm) | 15.88 | 19.05 | 19.05 | 22 | 22 |

Refrigerant liquid pipe (mm) | 9.52 | 12.7 | 15.88 | 19.05 | 19.05 |

maximum operating current (A) | 12 | 23 | 23 | 26 | 44 | 44 | 31 | 51 | 51 | 39 | 57 | 57 | 40 | 60 | 60 |

power cable specification (mm³) | 5x2.5 | 5x4 | 5x4 | 5x4 | 5x6 | 5x6 | 5x4 | 5x10 | 5x10 | 5x6 | 5x10 | 5x10 | 5x6 | 5x10 | 5x10 |

Indoor machine coagulation parameters |

|

Size:width*depth*height (mm) | 30ox1200x2000 | 300x1200x2000 | 600x1200x2000 | 60ox1200x2000 | 600x1200x2000 |

30Ox140Ox2000 |

GW (kg) | 190 | 230 | 285 | 310 | 330 |

Outdoor unit model | Standard type | CY0191-A1S | CY0451-A1S | CY0742-A1S | CY0893-A1S | CY0893-A1S |

Number of matches | pc | 1 | 1 | 1 | 1 | 1 |

① F: rear return air and front air supply, S: side return air and side air supply;

② The standard operating conditions are: indoor dry bulb temperature 37°C, relative humidity 24°C, outdoor dry bulb temperature 35°C;

③ The above table is only part of the parameters, the specific configuration is subject to the actual purchase nameplate, if you need more information about parameters, please contact our company.

Customized services

According to the situation, can customize a variety of air supply.

Optional: port condensate water strong drainage port support up to take over mode port SNMP and TCP/IP interface port dual power input

Note: In addition to the above functions, please contact our company for custom requirements.

Parameters of inter column air-cooled outdoor unit

Model IRW-CY | 191 | 451 | 742 | 893 | 893 |

Input power | 220Vac/1Ph/5OHz | 220Vac/1Ph/5OHz | 220Vac/1Ph/5OHz | 220Vac/1Ph/5OHz | 220Vac/1Ph/5OHz |

Installation method | tower | horizontal | horizontal | horizontal | horizontal |

Form of condensing fan | single phase asynchronous motor+axial flow fan blade | Ac axial flow fan | Ac axial flow fan | Ac axial flow fan | Ac axial flow fan |

Max current (A) | 1.7 | 3.5 | 7 | 10.5 | 10.5 |

Speed Control | stepless speed regulation | stepless speed regulation | stepless speed regulation | stepless speed regulation | stepless speed regulation |

Power cable specifications (mm) | 3x1.5 | 3x1.5 | 3x1.5 | 3x1.5 | 3x1.5 |

Outdoor unit structural parameters |

Size: W×D×H (mm) | 930x390x1270 | 1225x1076x960 | 2075x1076x960 | 2775x1076x960 | 2775x1076x960 |

WG (kg) | 65 | 76 | 138 | 169 | 169 |

① Nominal operating conditions for heat exchange: inlet temperature 35 ℃, condensation temperature 50 ℃.