The online battery inspection instrument is a powerful battery inspection instrument designed to meet the needs of DC screen systems. The instrument comes with 24 battery inspection functions, and each measurement port is isolated by an optical coupling, ensuring good safety and high accuracy in measurement. In addition, it can be extended to a maximum of 216 battery inspection functions through the RS485 interface. Suitable for both power and communication systems, single battery types are divided into 2V, 6V, and 12V, and should be specified when ordering; Adopting RS485 communication interface, the standard Modbus communication protocol can be directly connected to the monitoring system in the background.

Product Features

1) Single battery monitoring has overvoltage, undervoltage, and differential pressure alarm functions to accurately locate faulty batteries;

2) Detect the voltage and current of individual batteries, battery pack terminal voltage and current, environmental temperature of battery room and battery temperature, and measure the internal resistance of individual batteries; Calculate the maximum individual voltage and serial number of each battery pack, the minimum individual voltage and serial number of each battery pack, and the average individual voltage

3) Discharge measurement: Record discharge voltage, current, discharge capacity, and discharge time;

4) Powerful fault detection function, with unlimited number of faults, that is, how many faults are displayed;

5) Open communication protocol design, RS485 serial communication interface, support 1200BPS, 2400BPS, 4800BPS, 9600BPS Baud, realize telemetry, remote communication function, convenient connection with power automation system, and realize automatic inspection of battery system;

6) The system provides relay normally open contact output for fault information, that is, the output point is connected to the common point during alarm. The internal relay capacity is AC220V/3A, DC220V/0.2A. If the above parameters are exceeded, an intermediate relay should be used. The content can be freely set according to user needs (this is an option function);

7) The batteries are set and wired according to the actual number. For example, when there are 19 batteries, only BAT00 to BAT19 wiring needs to be completed. When there are more than 27 batteries, the battery inspection unit needs to be expanded through the 485 communication interface. At the same time, it can expand the detection function of 108 sections;

8) The battery inspection unit can be connected to the battery by installing a self recovery fuse at the battery terminal wiring to prevent damage caused by short circuits. Please pay special attention to the positive and negative terminals of the battery when wiring.

9) Adopting digital DSP as the core and imported optoelectronic isolation optocoupler to ensure stable operation of the system;

10) Through the LCD display screen, the human-machine interface visualization operation is achieved, with all Chinese menus, simple and convenient operation, and easy to get started;

11) Complete alarm processing and recording functions, which can quickly query the current fault content;

12) The precise management and strict control of individual battery voltage, total voltage, charging and discharging current, and battery internal resistance are key to protecting the battery and extending its service life. Users can set various alarm parameters themselves to automatically complete the precise management and maintenance of the battery;

Battery inspection unit

The battery inspection unit is used in conjunction with the battery online inspection instrument to expand the battery inspection instrument. The battery inspection form does not monitor the status of each battery, abbreviated as battery monitoring. Each unit can detect up to 24 individual battery voltages; The system can detect up to 2 sets of 120 individual batteries, meaning that a system can be configured with up to 10 battery detection units; It can detect 2V, 6V, and 12V individual batteries separately (specify the battery type when ordering), with a measurement accuracy of 0.2%; The detected individual battery information is transmitted to the main monitoring system through the RS485 bus.

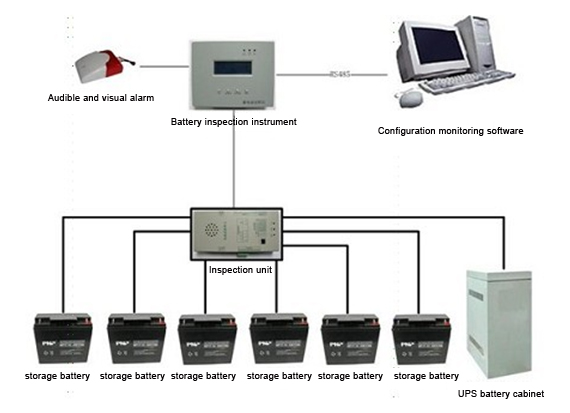

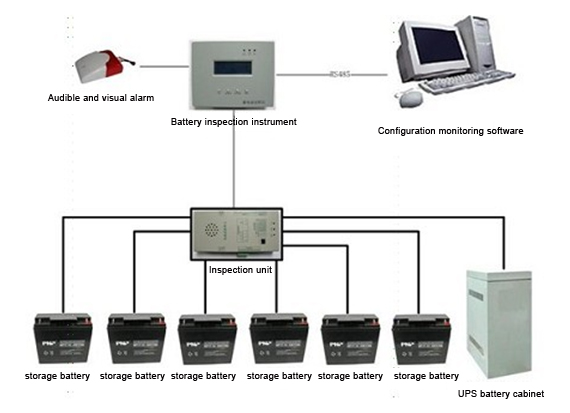

Application Topology Map